Excavating is the process of digging up any necessary dirt to prepare your site for masonry construction!

A new construction project is a big investment and requires a lot of planning and preparation. A commonly overlooked step in the construction process is preparing the actual site. You may think that starting construction is as easy as picking an empty lot and starting to build, but that is not the case. Here are the steps to preparing your site for masonry construction.

Rough Staking

This is the process of laying out the masonry construction project. This is an important step because it costs money to clear out a construction site, so it will save both time and money to know what needs to be done in advance. Rough stakes look like long sticks that are put into the ground to outline the area where the masonry construction will take place. This gives you and your masonry contractor an idea of what space they are working with.

Clearing

After the site is rough staked, the next step is to clear everything and make room for construction. Trees, roots, vegetation, and anything else that may be in the way need to be cleared. When clearing a spot, you must decide what to do with the debris. The easiest option (also the most expensive) is to hire someone to haul it away, but you could also opt to bury or burn it.

Excavation

If your masonry building is going to have a basement, then the ground will need to be excavated to accommodate for that. You will need to consider what to do with the excess dirt that is dug out of the ground. You may choose to use the dirt to fill in areas on the property that could use more dirt.

Rough Grading

Rough grading is when you shift dirt around to get the desired grade level that you want for your masonry construction project. When you do this, be sure to consider any drainage needs for the building. The best way to do rough grading is to cut and fill evenly in order to avoid those expensive hauling costs. This simply means that you want to use dirt you already need to dig up to fill open spaces and vise versa.

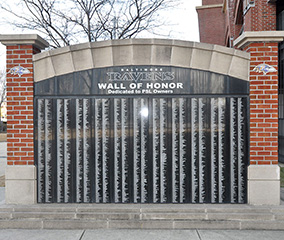

Contact Del Prete Masonry Today for Your Masonry Construction Project!

Whether you are ready to start your next masonry project or are still hesitant and have questions, Del Prete Masonry is here to help. We have the experience and expertise to get it right the first time. Questions? Want to visit some of our residential or commercial projects? Ready to set up a consultation? Feel free to give us a call at 410-683-0650 or visit us online. We are happy to serve Baltimore City and County, Harford County, Carroll County, Anne Arundel County, and Howard County. To see examples of our work and to keep up with our new and exciting projects, be sure to Facebook, Twitter, Google+, and Pinterest.