Here are some reasons why you should choose masonry materials for your construction project.

There are many building materials to choose from, and if you’re reading this then you could be considering going with masonry for your next construction project. There are a few pros and cons to any type of material, and if the expense and labor-intensive involvement of masonry materials is a turn off, then keep in mind that there are several benefits that make it worth it in the long run. Here are some reasons why you should choose masonry materials for your construction project.

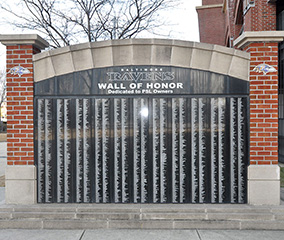

If you have been thinking of installing a masonry structure, then you may have already thought over the materials. And while concrete, limestone, and natural stone all have their benefits, have you considered brick? There are several reasons why brick might be the ideal choice for your masonry project.

If you have been thinking of installing a masonry structure, then you may have already thought over the materials. And while concrete, limestone, and natural stone all have their benefits, have you considered brick? There are several reasons why brick might be the ideal choice for your masonry project. Often when people think of demolition, they picture a big wrecking ball or a bulldozer. But even though demolition looks like it’s all about destruction and chaos, there is actually a very orderly system at play. Part of this system is the different methods of demolition, and each one has specific advantages depending on the situation. Here are the three main methods of demolition.

Often when people think of demolition, they picture a big wrecking ball or a bulldozer. But even though demolition looks like it’s all about destruction and chaos, there is actually a very orderly system at play. Part of this system is the different methods of demolition, and each one has specific advantages depending on the situation. Here are the three main methods of demolition.

Many people like the aesthetic of painted brick for the exterior structures. Painting your brick gives it an even texture and color. Also, painted brick gives it a protective coating against the elements and erosion. But if you have decided that you want to paint your brick then here are a few steps to take to make sure that it is done successfully.

Many people like the aesthetic of painted brick for the exterior structures. Painting your brick gives it an even texture and color. Also, painted brick gives it a protective coating against the elements and erosion. But if you have decided that you want to paint your brick then here are a few steps to take to make sure that it is done successfully.