Explore the far-reaching benefits of brick buildings with DelPrete Masonry.

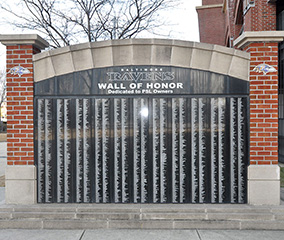

Brick has been a cornerstone of construction for centuries, and for good reason. In commercial construction, brick continues to be one of the most trusted and valued building materials available. Whether you’re designing a new office, retail center, school, or industrial facility, brick buildings offer a wide range of benefits that make them a smart investment for any property owner.

Explore with DelPrete Masonry the comprehensive advantages of building with brick and why it remains a go-to material in modern commercial masonry. (more…)